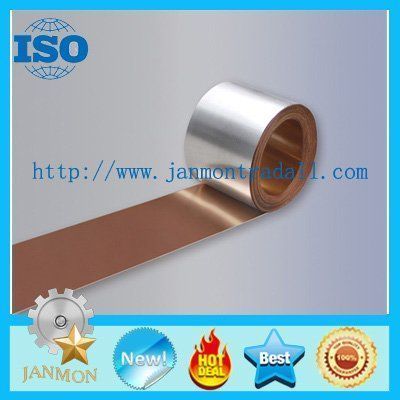

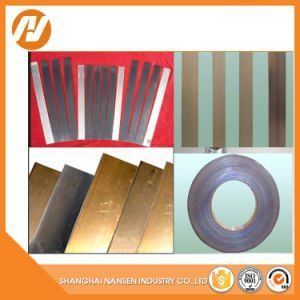

Bimet al strip for bearing

3 Feb SubsTech's sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related.

I Leona Age: 24. Full bareback possible.Maybe you like a mixture of both - never knowing who will turn up !

Want to find a partner you like Strip? Find

My name Evie Age: 33. I wish to meet generous gentlemen in the cityI will like to invite you to enjoy the benefits of my touchno anonimous numbers .

Process – Metal Powder (Hydra Atomization)

R G Bronze is manufacturing and delivering Plain Shaft Bearings, Bushings and Thrust Washers of Bimetal Strip - Steel Backed Sintered Copper Lead Alloy.

LATEST NEWS

Description:The rolls 30, 31 are heated by heaters 34 to a temperature within the range to F. The discharge end of the furnace is connected to a rolling mill 30, 3 1 by an air-tight chute 32 to permit transfer of the strip to rollers 30, 31 to prevent the formation of oxidation. For a better understanding of the present invention, together with other and further objects thereof, reference is had to the following description taken in connection with the accompanying drawings, and its scope will be pointed out in the appended claims. For carrying out the process in accordance with the invention, steel of the type commercially known as SAE has been found suitable as a steel backing member. The composition of the carbon steels is as follows: The method utilized herein avoids the cooling effect of the latter approach and the melting effect of the former by maintaining the rolls at a temperature below the melting point of the low melting point constituents but sufficiently high enough to obtain a satisfactory bond. Heretofore, the bonding of aluminum alloy to a steel backing member was accomplished by utilizing a temperature above the melting point of the low melting point constituent; the subsequent application of pressure upon the composite strip led to considerable squirting and dislocation of the low melting constituents.

User Comments 1

Post a comment

Comment: